Connectors should be reliable and robust; the processing should be quick and economical. THR (Through Hole Reflow) components, which can be soldered – together with SMT connectors – in a single reflow soldering process, meet these requirements. The required systems and processes for wave or selective soldering are not necessary.

A combination of the proven SMT and THT techniques

The reflow soldering combines the benefits of SMT (Surface Mount Technology) and THT (Through Hole Technology) in one process and is becoming more and more important due to the better mechanical strength. The components connect through the circuit board and are pressed into the soldering paste in the drill hole, this is why the method is also called “Pin in Paste”.

Temperature resistant and for automatic assembling

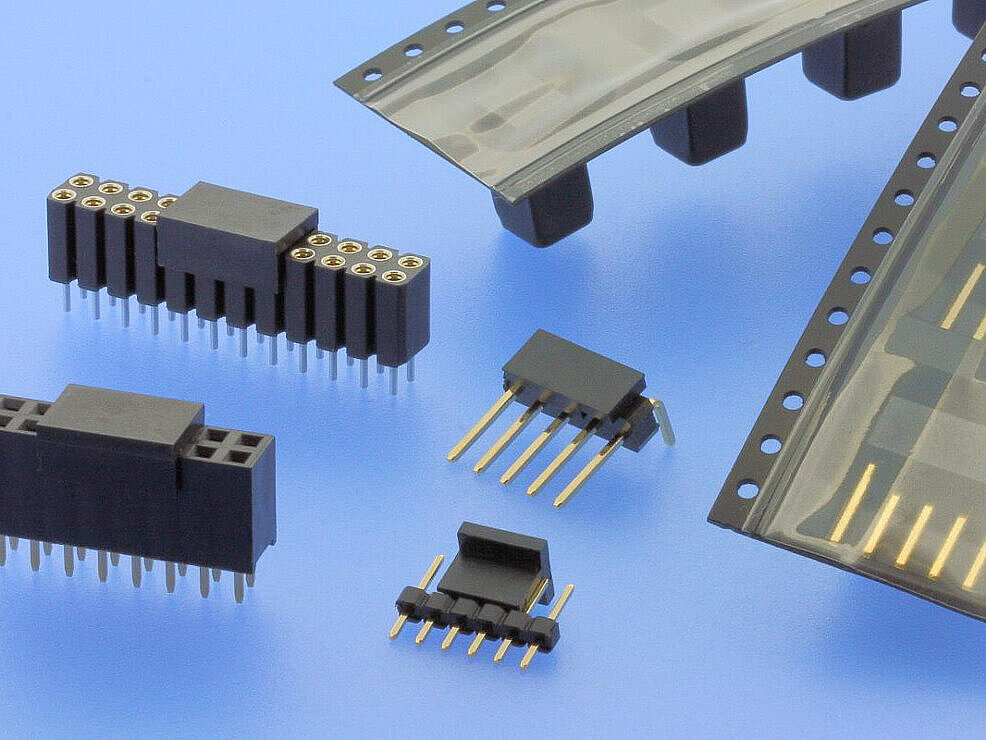

W+P offers a broad portfolio of THR capable products in the field of pin and female headers, precision female connectors and box connectors. Because of the high temperatures during the reflow process, the insulators are made of temperature resistant plastic according to UL94 V-0 and withstand up to 260° for 20 to 40 seconds, based on IPC/JEDEC J-STD-020C. On the side facing the circuit board, the housings are equipped with spacers, so that the heat in the reflow oven can optimally reach the contacts. The pin lengths are customizable to the different circuit board strengths and the height of the components can be processed with most assembly machines. For fully automatic assembly, the connectors are fitted with pick & place pads and can be delivered in tape & reel or tubes. Samples of THR connectors are available free of charge on request.